To maintain a strong market position & market share, we are enhancing innovation and speeding time-to-market.

It helps our organisation to maintain its competitiveness through analysis of current conditions within a specific sector or market.

Our R&D encompasses improvements in existing methods or processes, or wholly new processes, machines or systems.

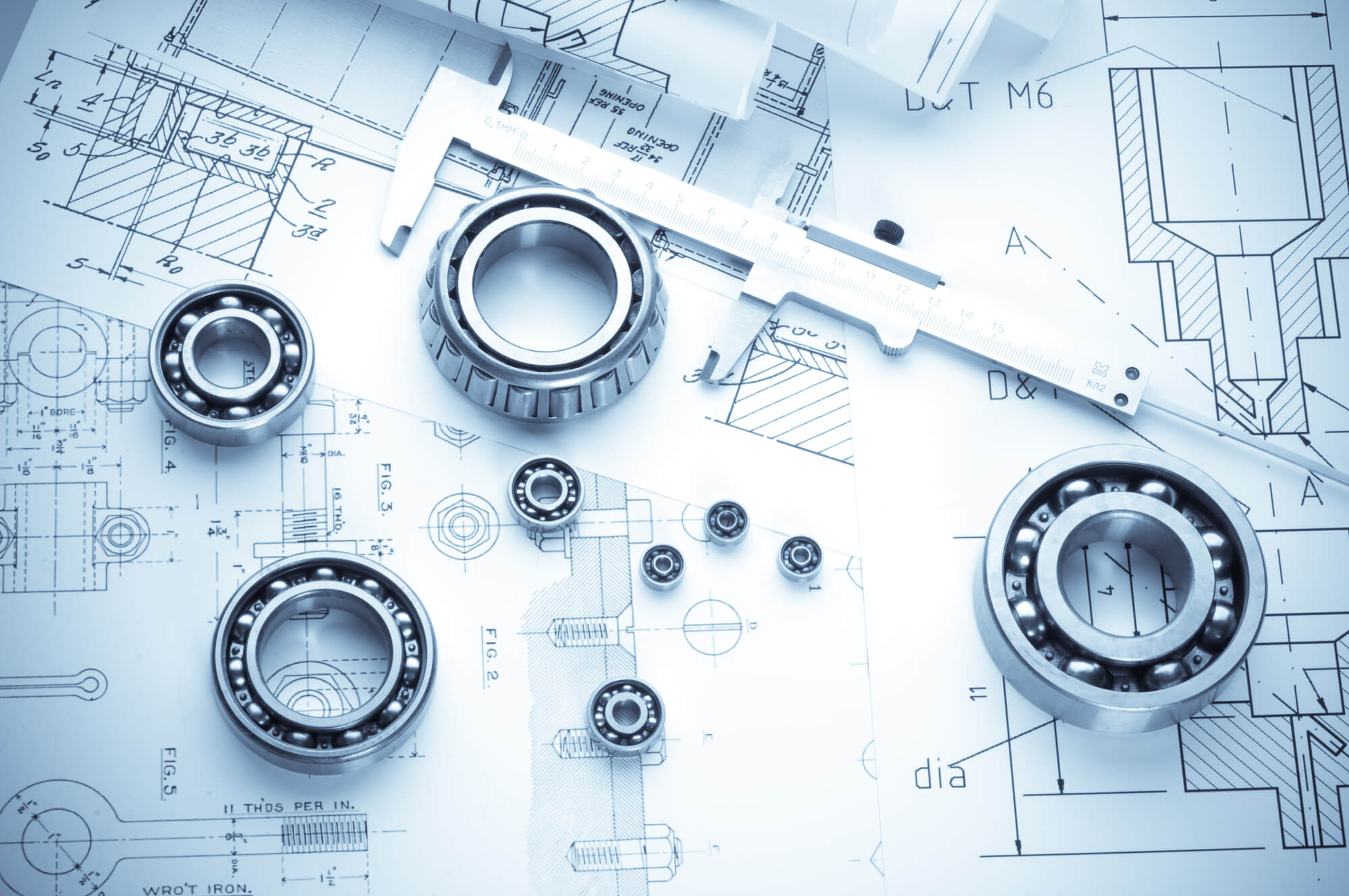

The main areas include development of new manufacturing processes, including new materials, coatings, methods, and practices associated with these processes.

We would like to enhance our brand and gain a reputation as an innovative business.

Due to an increase in costs and increasing pressure on margins, the mechanical engineering and construction department of NIRMITI group is optimizing its product development services. In order to gain an advantage early on, we concentrate on the product development times. We understand the importance of innovation in order to offer a competitive advantage and to adapt existing products within a minimal time period. We offer advanced engineering services and solutions for companies in various sectors. Our services in the field of mechanical engineering facilitate the development of complex products and mechanical designs. We offer our customers solutions from a single source throughout the entire product development cycle, from concept design to manufacture.

CAD allows for the easier development of products and product management integration.

Therefore to support our research & development activity, use of CAD systems is a necessity.

It aids in the creation, modification, analysis, or optimization of a design.

The softwares used are Creo, CATIA, AutoCAD, etc..

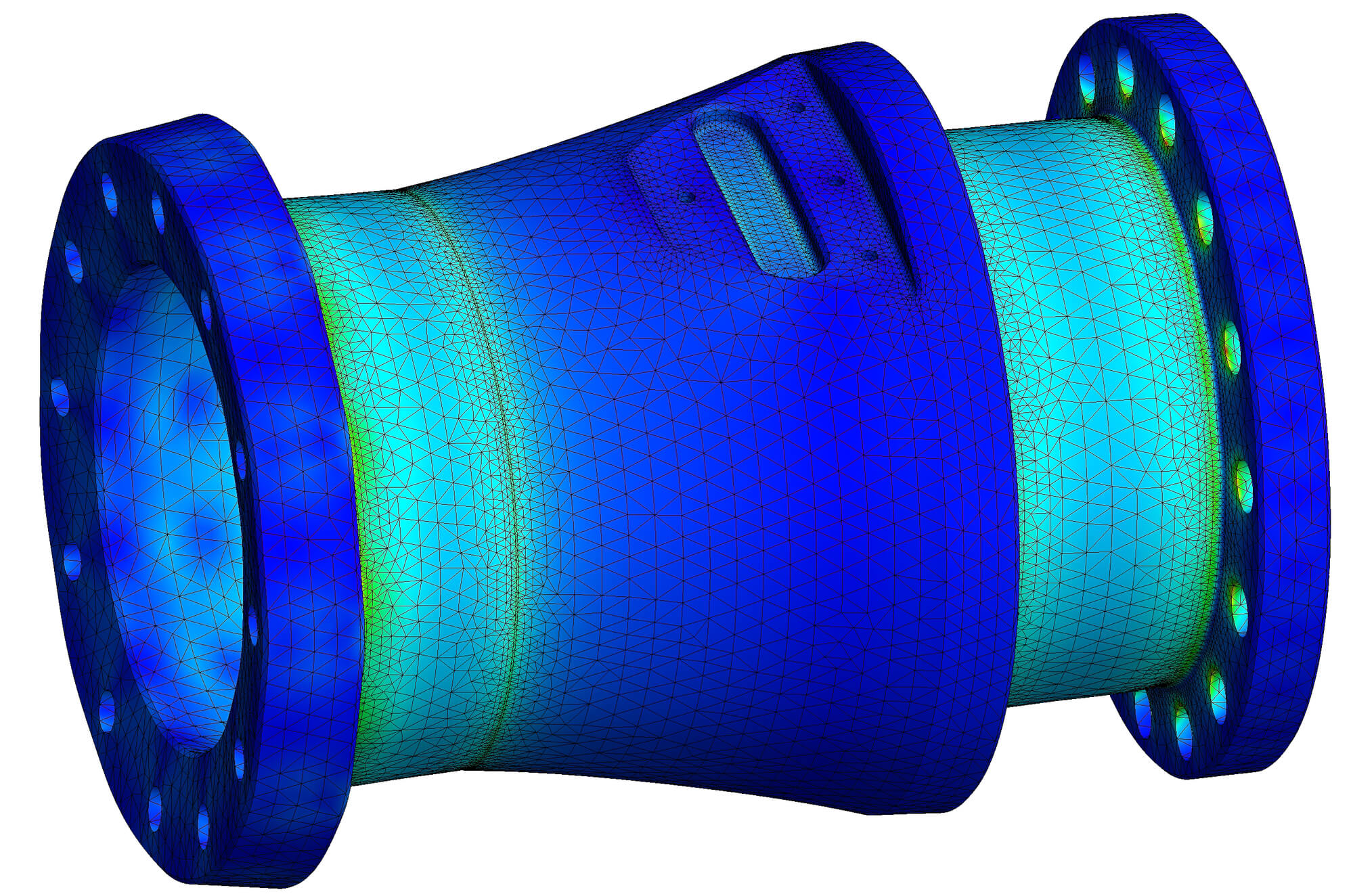

This is the additional facility which reduces the number of physical prototypes and run virtual experiments to optimize the designs.

It has a wide scope in aerospace, automotive, biomedical, chemicals, electronics, energy, geotechnical, manufacturing, and plastics industries.

With prototypes, we can refine and validate our designs so that we can release the right products at right time.

We have all the manufacturing capabilities & facilities for prototyping of new designs.

The objective of product design is to create a good or service with excellent functional utility and sales appeal at an acceptable cost and within a reasonable time.

The product should be produced using high-quality, low-cost materials and methods.

We involve our team from idea generation to commercialization with a systematic approach.

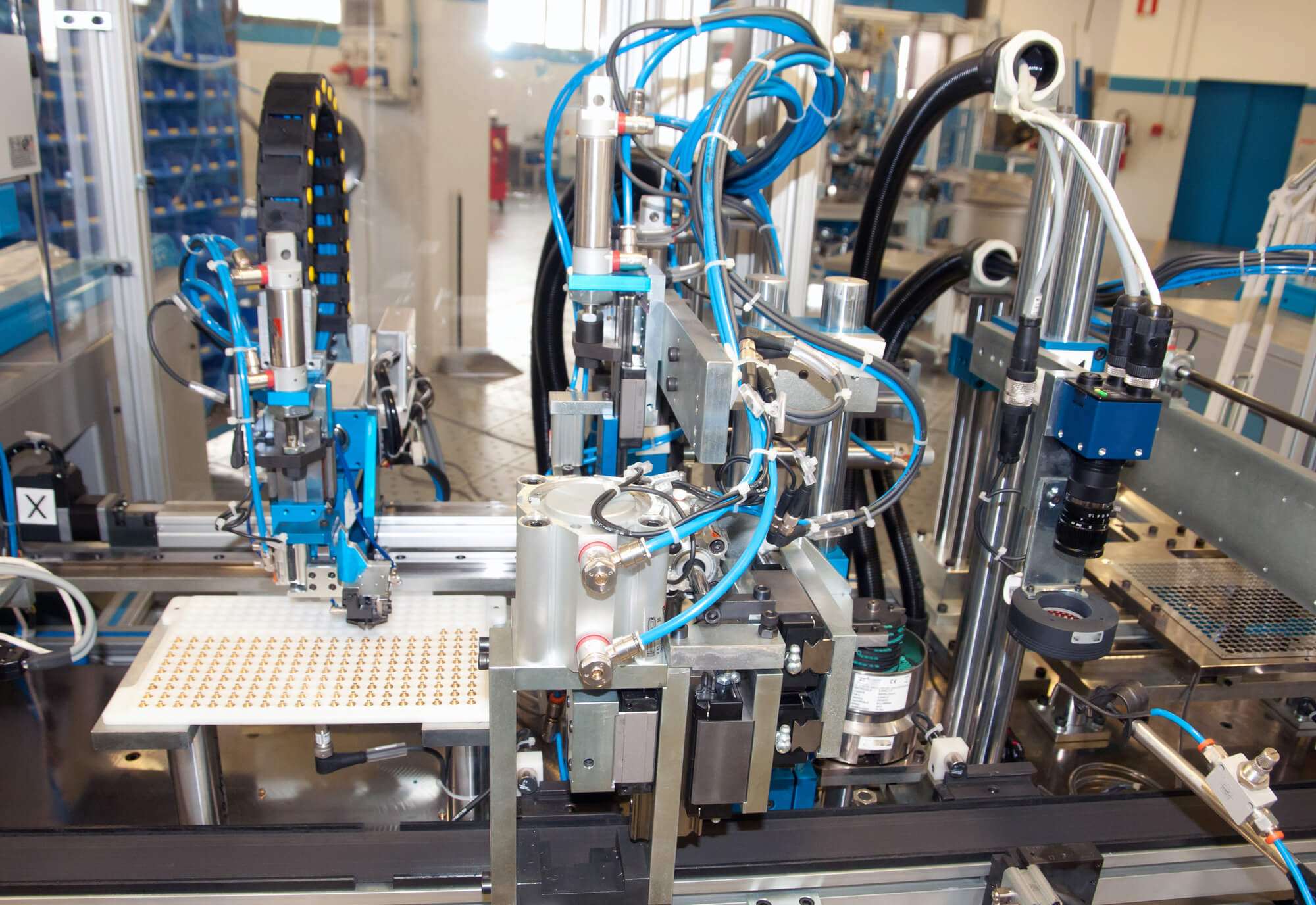

We have a skilled manpower for assembling complicated products with precision.

We also take projects to design CNC controlled assembly lines with defect free product output.

The required tooling, jigs & fixtures are also designed & manufactured by us.

We have established logistical packaging system with respect to the internatinal regulations by the use of recyclable packaging & minimal use of hazardous substance.

Our logistics system caters all the requirements related to process of planning, implementing and controlling procedures for the efficient and effective transportation.